The answer is consists of several factors, including but not limited to:

Depending on how you’d like to automate, (shrink systems, bagging equipment, stretch wrappers, and case sealing/forming machines) each group of machines can be segmented into 2 groups – semi-automatic and fully automatic.

Generally, semi-automatic equipment includes an operator starting the process and machine finishes. A fully-automatic system starts the process and finishes it with minimal operator assistance. For example, on a very basic semi-automatic stretch wrapper, the fork lift driver places the pallet of product on the turntable, attaches the tail of the film to the pallet and presses a button to start wrapping. Once completed the fork lift driver will cut the film. Finally, the fork lift driver will pick-up the pallet and move it.

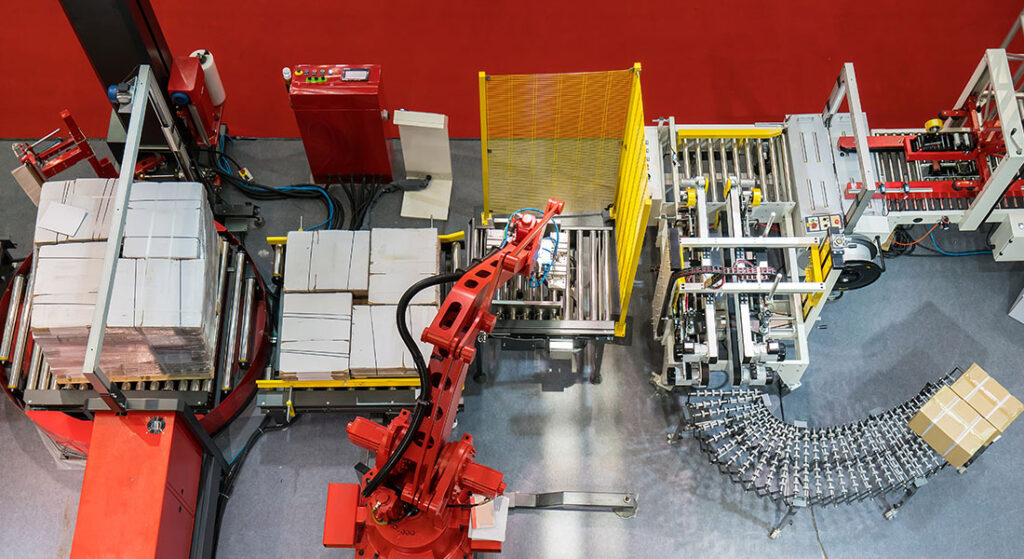

Using this similar example on a fully-automatic system, the pallet of product is placed on a powered indeed roller conveyor that either just discharged the pallet onto this conveyor (such as a palletizer) or to maximize throughput, the fork lift driver loads the infeed conveyor with pallet(s). The pallets will travel one at a time into the wrap zone and by way of sensors, begin the wrapping process. Once completed, the film is cut automatically and the pallet is discharged onto the outfeed conveyor waiting for the fork lift driver to get the pallet. In this scenario the fork lift driver has time to get other pallets instead of waiting for the wrapping process in our semi-automatic example.

Which are you? PNC has the experience and expertise to assist you by determining if and when your organization is prepared to move into a semi-auto or fully-auto application.

Get inspired. Begin your journey to packaging greatness today. 1-888-604-5185

Get inspired. Begin your journey to packaging greatness today.

1-888-604-5185

© 2024 Piedmont National Corporation. All rights reserved.